Case Study: Didling Farm, West Sussex

Didling Farm comprises 316 hectares, with 194 ha available for grazing, but of variable pasture quality. Shortly after taking over as flock manager, Matthew identified various challenges that could be improved upon to make the business more efficient and therefore profitable

1) Lamb outputs: the numbers of lambs produced, the number of lambs achieving finishing weight and the actual finished liveweights were all lower than they could have been

2) Cost control: the utilisation of grass at pasture and the conserved forage for winter holding were not effectively managed so the yield of each was lower than the potential

3) Breeding programme: bearing in mind that the land is prone to being very wet in winter and conversely very dry in summer, and considering the associated worm restraints, the flock could consist of sheep with the genetics best suited to making the farm profitable

Matthew started by looking at the breeding programme: the flock initially consisted of Charolais and Rouge cross mules all bought from one estate, which were put to Beltex, Texel and South Downs tups.

Matthew started by looking at the breeding programme: the flock initially consisted of Charolais and Rouge cross mules all bought from one estate, which were put to Beltex, Texel and South Downs tups.

He focused on Lleyn ewes as they are smaller, meaning he could get more to the acre, and more prolific, and introduced just under 20% of Lleyn ewes to the flock, to home-breed the replacements. He began collecting data on them to compare with the rest of the existing flock and quickly noticed that the Lleyns were got up to 30kg quickly, but then plateaued and were slow to achieve finishing weight. He continued to phase out the Charolais x Rouge mules and then brought in Innovis Aberfield rams to cross with the Lleyns. This cross seems particularly suited to the pasture growing on Didling’s chalky soil as the sheep now gain the extra 10kg at the same point at which the pure Lleyn reached 30kg. Matthew continues to tweak the breeding programme to see if further improvements can be made.

At this stage, all data was being recorded via pen and paper, so with the goal of collecting more accurate data, Matthew introduced EID in 2006 – long before it was mandatory. The initial focus was on recording liveweights – how fast the lambs were growing between dates and the finished liveweights. He then looked at the benefits on liveweights of winter shearing, and by collecting data regularly saw an associated increase of 25% in the birth weight of the lambs, as the ewes’ intake of good quality forage between shearing and lambing increased. The increased value of finished lambs exceeded any additional cost of winter forage, so showed that winter shearing was beneficial to his flock.

At this stage, all data was being recorded via pen and paper, so with the goal of collecting more accurate data, Matthew introduced EID in 2006 – long before it was mandatory. The initial focus was on recording liveweights – how fast the lambs were growing between dates and the finished liveweights. He then looked at the benefits on liveweights of winter shearing, and by collecting data regularly saw an associated increase of 25% in the birth weight of the lambs, as the ewes’ intake of good quality forage between shearing and lambing increased. The increased value of finished lambs exceeded any additional cost of winter forage, so showed that winter shearing was beneficial to his flock.

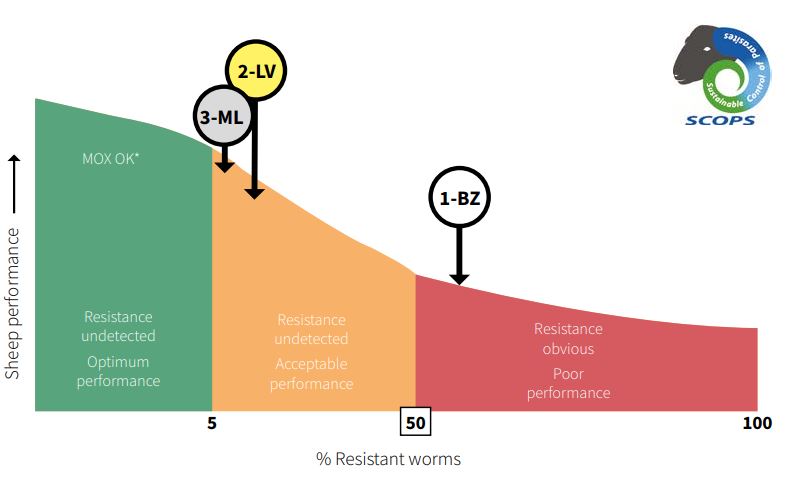

In September 2007, shortly after Matthew took over as flock manager, a high number of lambs died. Post mortems identified that the cause of death was Pasteurella pneumonia, but that the underlying cause was actually high worm counts: the heavy worm burdens put the animals under stress meaning that they were susceptible to the Pasteurella infection. Faecal analysis identified the flock had treble resistance – to benzimidazoles, levamisoles and macro-cyclic lactones.

The resistance was carefully managed by fully adopting Faecal Egg Counts (FECs) and using a targeted approach to worm management, namely rotating active ingredients and being highly specific with the choice of product and timing of use. As Matthew had been involved in testing the Techion FECPAK diagnostic platform before its release to the UK market in 2014, he used this tool for accurate analysis. The strategic approach to worm control has contributed to the overall improvement in the performance of the flock year on year.

At the same time, Matthew looked at pasture management. Starting with a good old fashioned ruler, he measured the length of the grass throughout the year, to ensure he wasn’t wasting good growth that could be harvested for hay and silage for winter forage, and recorded all measurements. He noticed that some paddocks yielded far more volume and quality grass, than others, so adjusted his land management approach to make the most of the higher-yielding paddocks, and not overgraze the poorer-yielding ones. He then tried using plate meters for measuring grass length but found too many inaccuracies, particularly in late spring/early summer, so prefers to use a sward stick to accurately record the data throughout the year. Measuring the dry matter yield – the grass content that the sheep actually digests – and trace element content has further helped with making the most of the land and pasture available, and feeding strategies.

At the same time, Matthew looked at pasture management. Starting with a good old fashioned ruler, he measured the length of the grass throughout the year, to ensure he wasn’t wasting good growth that could be harvested for hay and silage for winter forage, and recorded all measurements. He noticed that some paddocks yielded far more volume and quality grass, than others, so adjusted his land management approach to make the most of the higher-yielding paddocks, and not overgraze the poorer-yielding ones. He then tried using plate meters for measuring grass length but found too many inaccuracies, particularly in late spring/early summer, so prefers to use a sward stick to accurately record the data throughout the year. Measuring the dry matter yield – the grass content that the sheep actually digests – and trace element content has further helped with making the most of the land and pasture available, and feeding strategies.

While he noticed immediate improvements in both flock and land management as a result of the strategic changes he’d made, it was really after collecting all of the EID flock data and the pasture management data for 3 years that Matthew saw consistent and repeatable improved returns – proving that the amended strategy was working.

In 2012, AHDB approached Matthew to help develop a UK model of FARMAX, the New Zealand decision support tool for farmers. He started by modelling indoor vs outdoor lambing, to see the potential financial benefits for his flock, and as he had so much data already, was able to identify that shifting lambing from early March to late March would coincide with peak grass growth at Didling. Since then he has collected data on all aspects of flock and pasture management, including parasite management, lamb health (including in-turned eyelids), the benefits of different protein supplements pre-lambing and trace elements in feed, sub soiling and monthly soil temperatures.

In 2012, AHDB approached Matthew to help develop a UK model of FARMAX, the New Zealand decision support tool for farmers. He started by modelling indoor vs outdoor lambing, to see the potential financial benefits for his flock, and as he had so much data already, was able to identify that shifting lambing from early March to late March would coincide with peak grass growth at Didling. Since then he has collected data on all aspects of flock and pasture management, including parasite management, lamb health (including in-turned eyelids), the benefits of different protein supplements pre-lambing and trace elements in feed, sub soiling and monthly soil temperatures.

All of this data collection and modelling different variables through the FARMAX software proved to be particularly beneficial in the summer drought of 2018: as there was now so much historic data of the pasture, Matthew could compare that year’s growth to previous years and knew that there would not be sufficient pasture to support both the ewes and all of that year’s lambs. He then identified the lambs which were underperforming at 90 days post-lambing and sold these off as stores. This meant that the remaining ewes in particular would have enough pasture for the rest of the year, so the number of lambs conceived for next year’s lambing would not be affected, and there was still sufficient hay and silage for the entire winter. The changes made based on the data comparison provided a 2 year benefit to the farm!

This case study proves that there are long term benefits to data collection for developing management strategies. To discuss ways in which Matthew could support your business too, contact him here.